Beginner Metal Laser Cutting Tips

10 things to keep in mind when designing a metal laser cut project

Metal laser cutting is an excellent way to manufacture a product with a quick turnaround time, low cost, and high precision. Anyone with access to a design program and contact info for a high quality metal shop equipped with a laser cutter (i.e. Sattler Manufacturing) can start creating any laser cut metal product they can dream up.

However, there are several things to keep in mind when designing a project for laser cutting. Metal laser cutters cut 2D shapes out of flat metal sheets (think of a laser jet printer) so designing 3D parts and projects is definitely possible, but will require some further assembly and smart design work.

If you’re ready to use metal laser cutting fabrication, here are 10 important things to keep in mind when preparing for a metal laser cut project. (And when you’re done with this guide, be sure to read our advanced tips for metal laser cutting for even more detailed guidance.)

10 Essential Tips for the Perfect Laser Cut Metal Project:

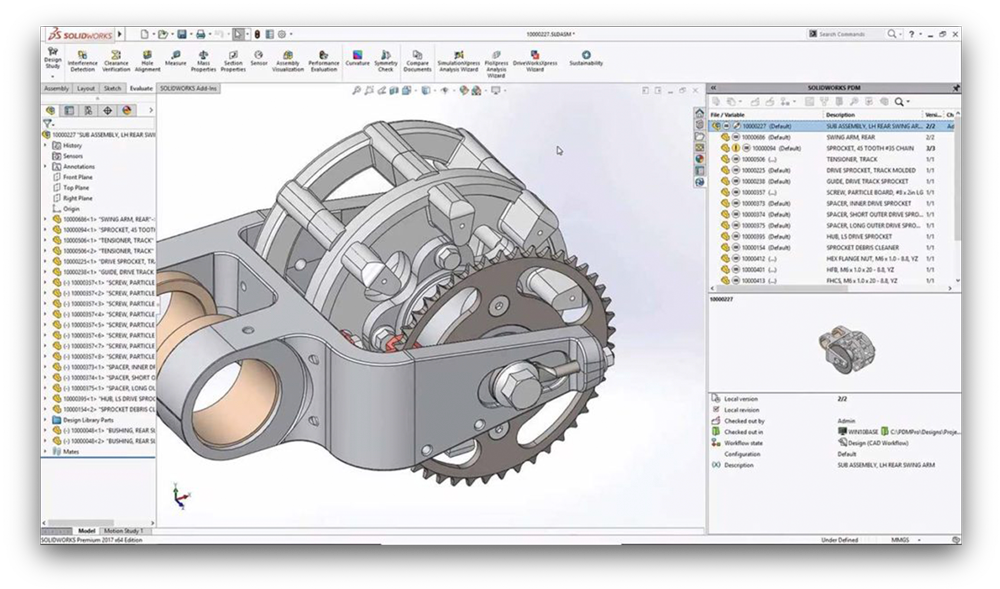

A metal fabrication project in SOLIDWORKS.

1. Use the right software program

Laser cutters require a vector file (typically in .dxf format) to be able to properly create the design. Programs that are appropriate to use for creating designs for laser cutting include Adobe Illustrator, AutoCAD, and Inkscape. One of our favorites is SOLIDWORKS, and we have a full breakdown of training resources for it available here.

2. Simplify, simplify, simplify

Try to create simple shapes that will be clearly visible in your finished project, especially if you are making a sign or piece of art, and avoid making too many unnecessary intricate designs when creating parts for assembly.

3. Create the design at full scale

Make sure the design is full scale (1:1) before sending to the laser cutter. Otherwise, you may end up with a sign or machine part more suited to a dollhouse than the purpose you intended.

4. Consider the type of material

Be sure that the properties of the metal material you are using are appropriate for its intended use. For example, aluminum does not rust and makes beautiful signs, but it is very soft and flexible. Steel is the most popular metal for industrial and commercial laser cutting , and here is a rundown of the most poplar kinds of steel.

5. Design internal shapes no thinner than the metal sheet itself

Don’t use design elements that are thinner than the thickness of the metal sheet, because it can affect the integrity of the part.

6. Convert all text into shapes

The laser cutter cannot process text boxes that have not been converted to a vector shape in the design program. Double check all text boxes and ensure they are converted into a shape.

7. Remove extra notes before sending the file

Clean your file of any extra notes, template guides, or unnecessary data. Don’t trust that just because the extra stuff is on a different layer, hidden, or outside the margins of your layout that it won’t be incorporated by another computer’s software.

8. Don’t send multiples or combine designs

If you need multiple pieces or designs, only send one of each design in separate files. Indicate how many you need of each design and the metal shop will take care of fitting the designs appropriately onto the sheet metal for minimal waste.

9. Consider turnaround time and shipping costs

Talk with your metal shop about how long it will take to finish your project and get it shipped to you, and take that into account when sending it off. Rush projects are always much more expensive, so plan enough time before you need your project to be finished. Also, consider how much shipping costs will be for large, heavy, or awkwardly shaped parts and plan it into your budget.

10. Be creative!

Metal laser cutting is a fast and fascinating process and has so much potential in both the creative and practical worlds. Have fun and enjoy the process of creating parts for your business, products to sell, or passion projects!

If you are looking for a metal shop equipped with a state of the art CNC laser cutter, look no further. Our team at Sattler Manufacturing has over 40 years of experience in the metal fabrication business, and laser cutting is one of our top specialties.

We are a family owned shop in the Nashville, Tennessee, area, and we work daily with .dxf files and CNC machining to fabricate an endless variety of 2D and 3D machine parts, signs, art, and metal products from sheet metal. The CNC laser cutting machines we utilize in our shop are incredibly fast and precise, and they create beautiful finished products with high accuracy. If you have any additional questions or would like a quote on your next project, please contact us today! Our friendly and highly experienced team is standing by to help you with any project you can dream up. We look forward to hearing from you soon!